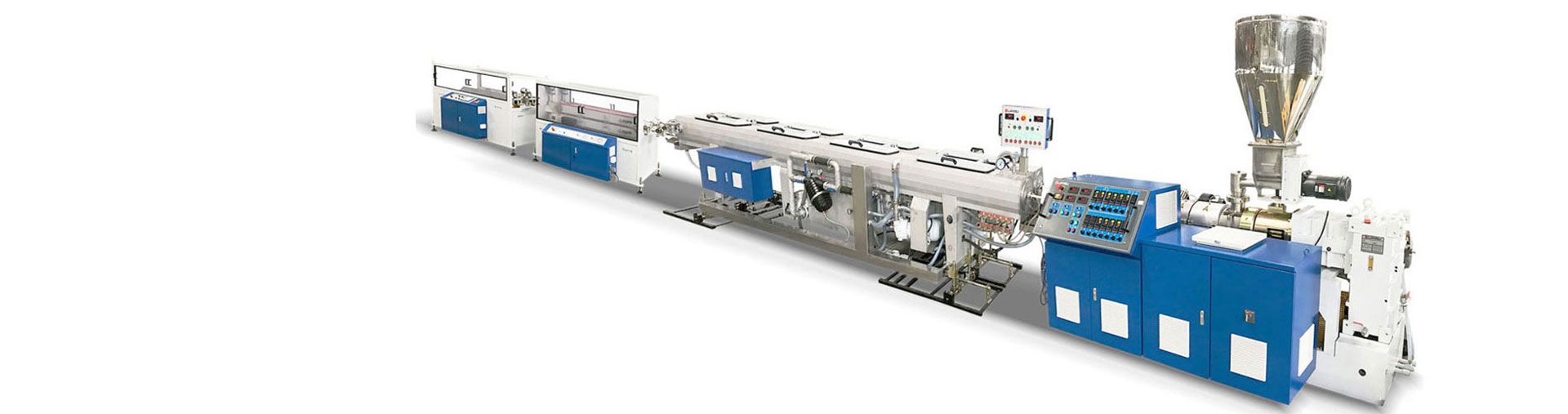

Ligne de production à double tube UPVC

Ø16-Ø110

GAMME DE TUYAUX (mm)

16x2

PORTAGE MAXIMAL (m/min)

23-36

LONGUEUR DE LIGNE (m)

280-750

SORTIE MAXIMALE (kg/h)

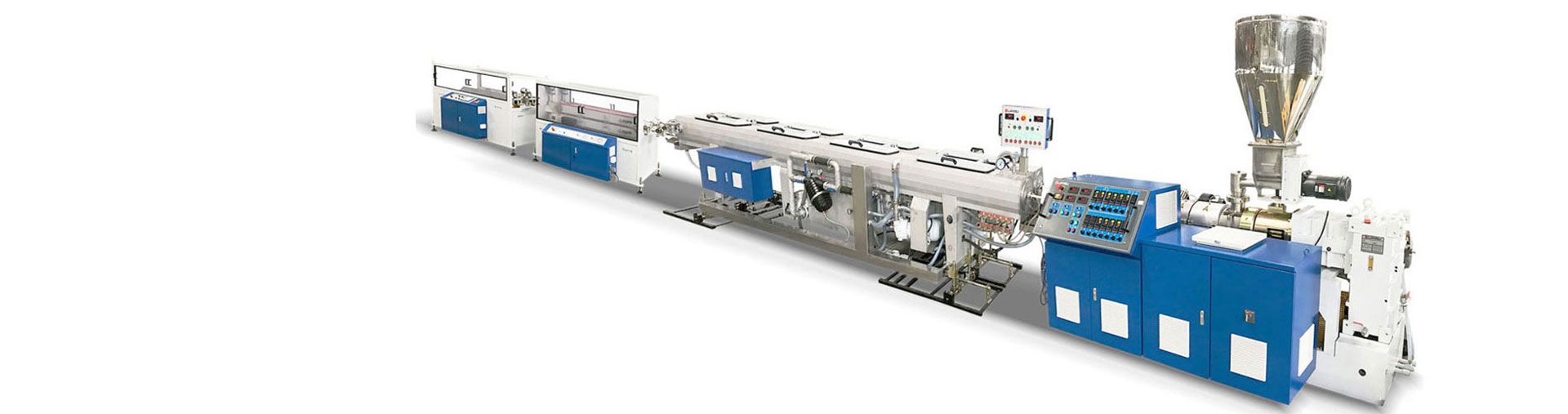

Ligne de production à double tube UPVC

Ø16-Ø110

GAMME DE TUYAUX (mm)

16x2

PORTAGE MAXIMAL (m/min)

23-36

LONGUEUR DE LIGNE (m)

280-750

SORTIE MAXIMALE (kg/h)

AVANTAGE DU PRODUIT

The main machine is equipped with large L/D ratio parallel twin-screw and conical twin-screw extruder, equipped with special permanent magnet synchronous servo motor for extruder, which is high-output and energy-saving.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

Equipped with on-line automatic packing mechanism, efficient and labor saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

The main machine is equipped with large L/D ratio parallel twin-screw and conical twin-screw extruder, equipped with special permanent magnet synchronous servo motor for extruder, which is high-output and energy-saving.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

Equipped with on-line automatic packing mechanism, efficient and labor saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

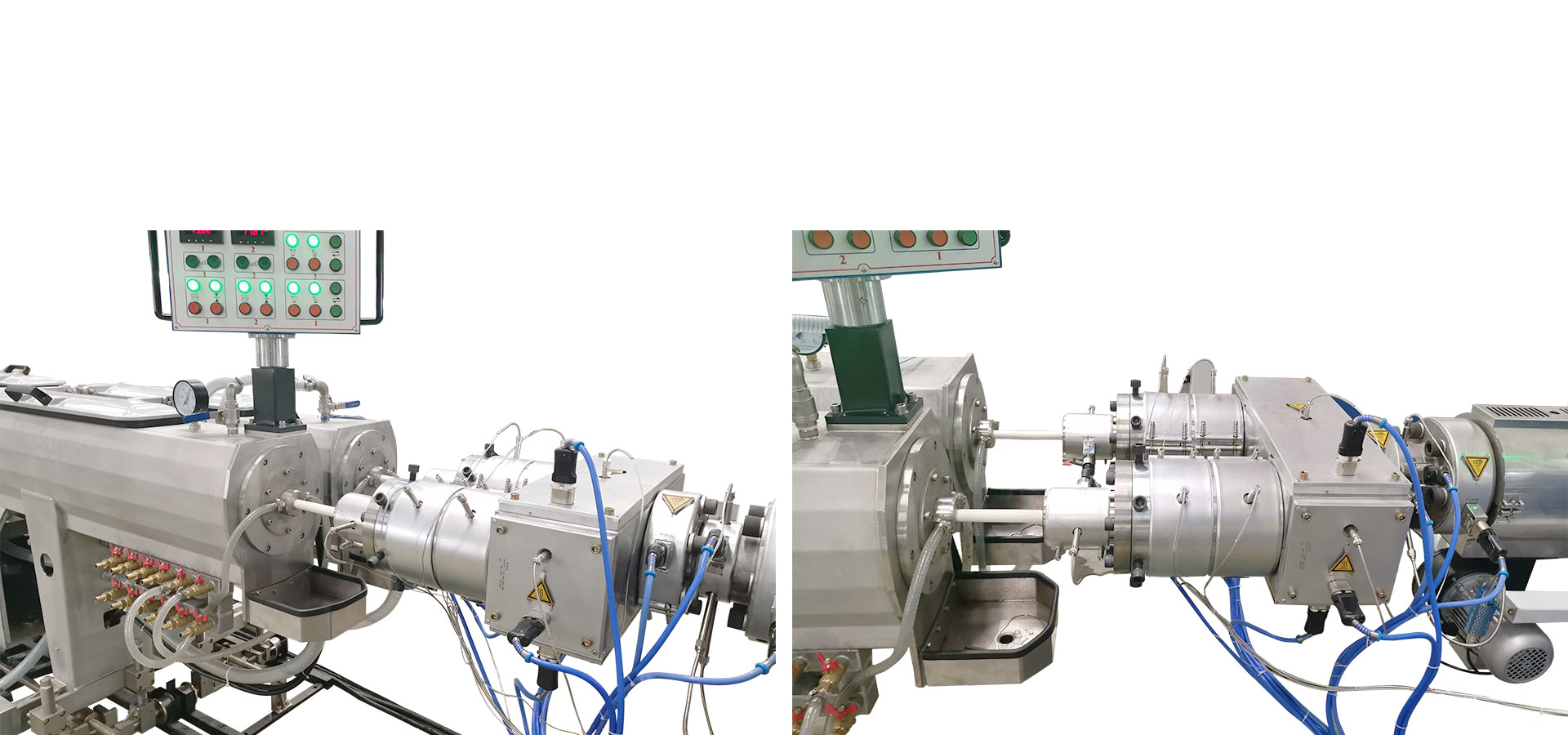

Extruder

Mould Design

Mould Design

Vacuum Tank

Vacuum Tank

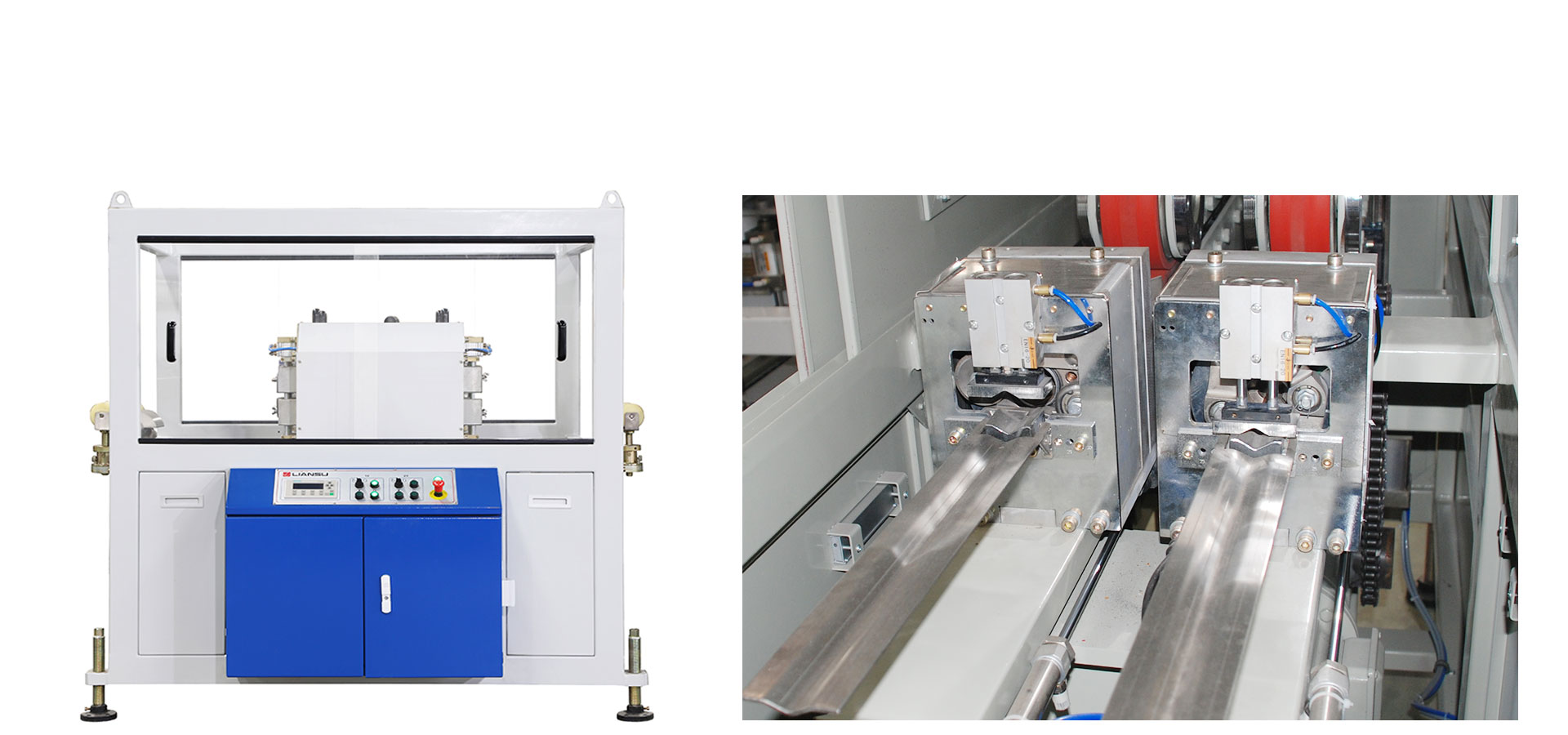

Haul-off Unit

Cutter

Cutter

On-line Auto Packaging Device

On-line Auto Packaging Device

Technical Data

* Test et acceptation basés sur la formule standard de Liansu

ÉCHANTILLON